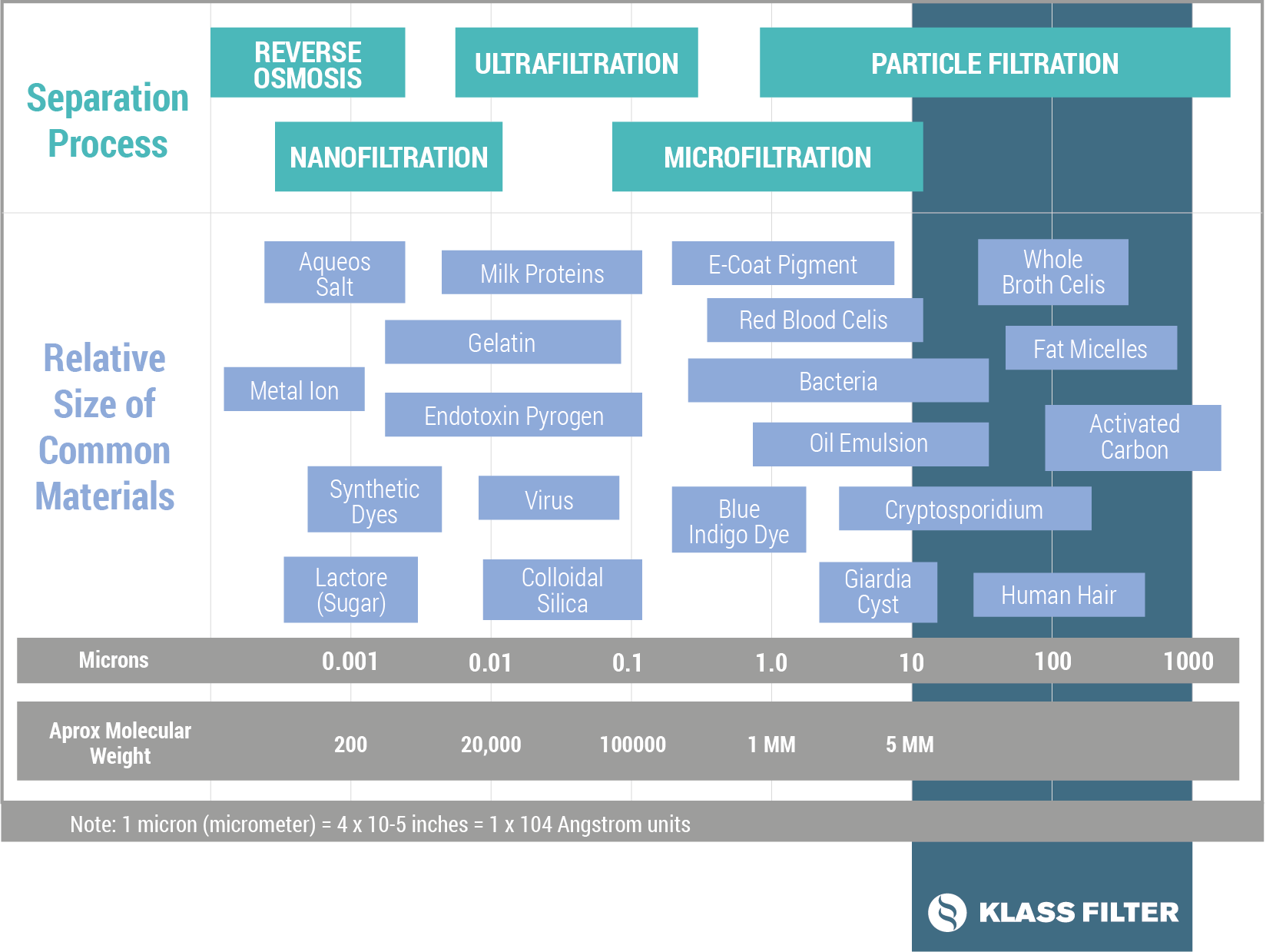

Klass filters are used in the area between 10μm and 1000μm for filtering suspended, sedimentary and floating particles.

Filtration solid/liquid separation

The patented Klass spiral filter is ideally suited for solid/liquid separation. It is used for thickening and dehumidifying suspensions (especially for fine separation of very fluid media). Areas of application are for example:

- fine separation after the press screw

- better phosphate separation

- reduction of storage capacity

- cleaning of the process liquid

- reduction of transport routes

- reduction of storage costs

- purification of press water

- low space requirement

- low space requirement

- reduced storage costs

- binding of up to 50 % phosphate (in old manure)

- reduction of the required discharge area

- reduction of the liquid manure storage area

- higher reimbursement for recycling in biogas plants

- significantly reduced disposal costs

- easy application (with separated fresh manure)

- better gas yield (with separated fresh slurry)

- improvement of the stable climate

- minimum space requirement

- simple assembly

- can even be easily integrated into existing systems at a later date

- maintenance-free with high throughput

- no filter change

- no process interruption

- low noise emission

Water recovery and purification

Economical and cost-efficient use of the valuable resource water is the top priority. Our filter systems consisting of Klass coarse filters, Klass jet wing liquid filters and Klass flow regulators enable maximum ecological and economical use of waste, process and service water. Areas of application are for example:

- continuous working mode

- minimum maintenance effort

- long service life of the HD pump

- low energy consumption

- high throughput (400 l/min.)

- minimum space requirement

- no filter change

- no switching to parallel systems

- no process interruption

- minimum space requirement

- no filter change

- no switching to parallel systems

- maintenance-free with high throughput

- no filter change

- no process interruption

- low noise emission

- preparation for irrigation systems

- maintenance-free with high throughput

- no filter change

- no process interruption

- low noise emission

Cleaning of process and waste water

In order to achieve the highest possible throughput, the motto is ‘as coarse as necessary’: Above all the Klass jet wing liquid filter proves its functionality with a high proportion of dirt in the water. It separates floating, suspended and sedimented matter of more than 25 µm from production water. These are then returned to the production cycle cleaned and treated without interrupting the production process. Areas of application are for example:

- continuous working mode

- minimum maintenance effort

- long service life of the HD pump

- low energy consumption

- high throughput (400 l/min.)

- minimum space requirement

- no filter change

- no switching to parallel systems

- no process interruption

- minimum space requirement

- no filter change

- no switching to parallel systems

- maintenance-free with high throughput

- no filter change

- no process interruption

- low noise emission

- preparation for irrigation systems

- maintenance-free with high throughput

- no filter change

- no process interruption

- low noise emission